Armor Penetration Model

|

Armor Penetration Model

|

Source: ADSS MRL Report MRL-R-675: Criteria for the Selection of Homogenous Armor (1.34~ MB PDF)

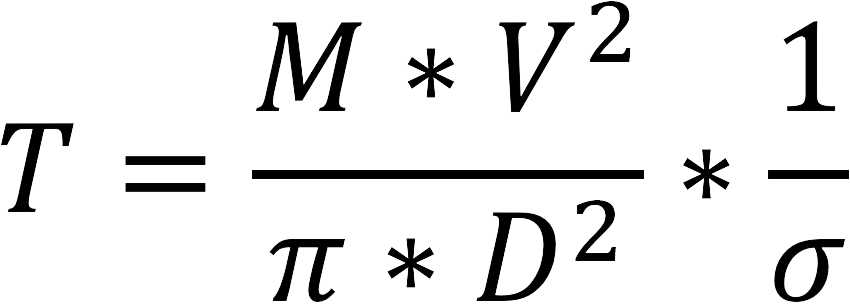

In this, the Australian Defence Scientific Service - Materials Research Laboratory puts forth a simple plug model, which is:

Where:

T = Thickness of Material Perforated (millimeters)

D = Diameter of Projectile (millimeters)

M = Mass of Projectile (grams)

V = Striking Velocity (m/sec)

σ = Ultimate Tensile Strength of Target (Megapascals)

σ for various armors is given as:

CS 1020 Hot Rolled Mild Steel: 976 MPa

SAE 4130 Steel (300 HV5 Hardness): 1240 MPa

SAE 4130 Steel (350 HV5 Hardness): 1420 MPa

SAE 4130 Steel (400 HV5 Hardness): 1600 MPa

P8 Hadfields Steel (Hot Rolled): 1690 MPa

5083 Aluminum Alloy (Cold Rolled): 452 MPa

7039 Aluminum Alloy (Aged): 638 MPa

Titanium - Commercial Purity (Mill Annealed): 800~ MPa

Titanium 318 Alloy (Forged+Annealed): 1685 MPa

Titanium 8 Al-1 Mo-1 V Alloy (Hot-Rolled Annealed): 2020 MPa

Pre-Built Calculator for ADSS-MRL Shear Plug ModelProjectile Mass (grams) Projectile Striking Velocity (m/sec) Projectile Diameter (mm) Ultimate Tensile Yield of Target (MPa) Penetration (mm) (0 deg) |